|

|

|

�@ |

E-mail�Gservice@ding-hui.com.tw ADD�G11F, No.42, Sec. 4, Cheng-gong Rd., Taipei, Taiwan, R.O.C. |

�@

|

Product |

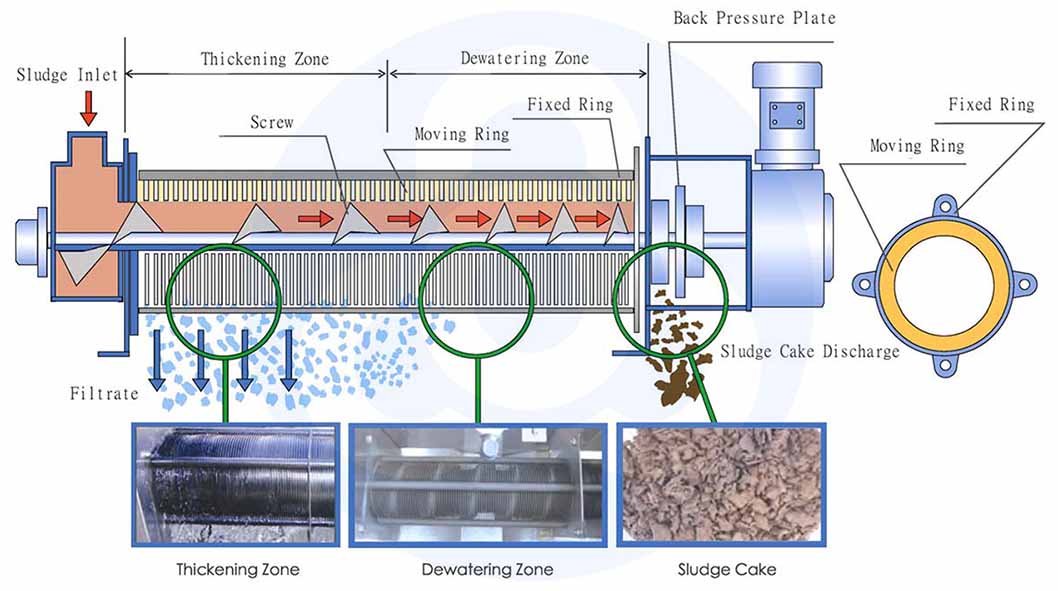

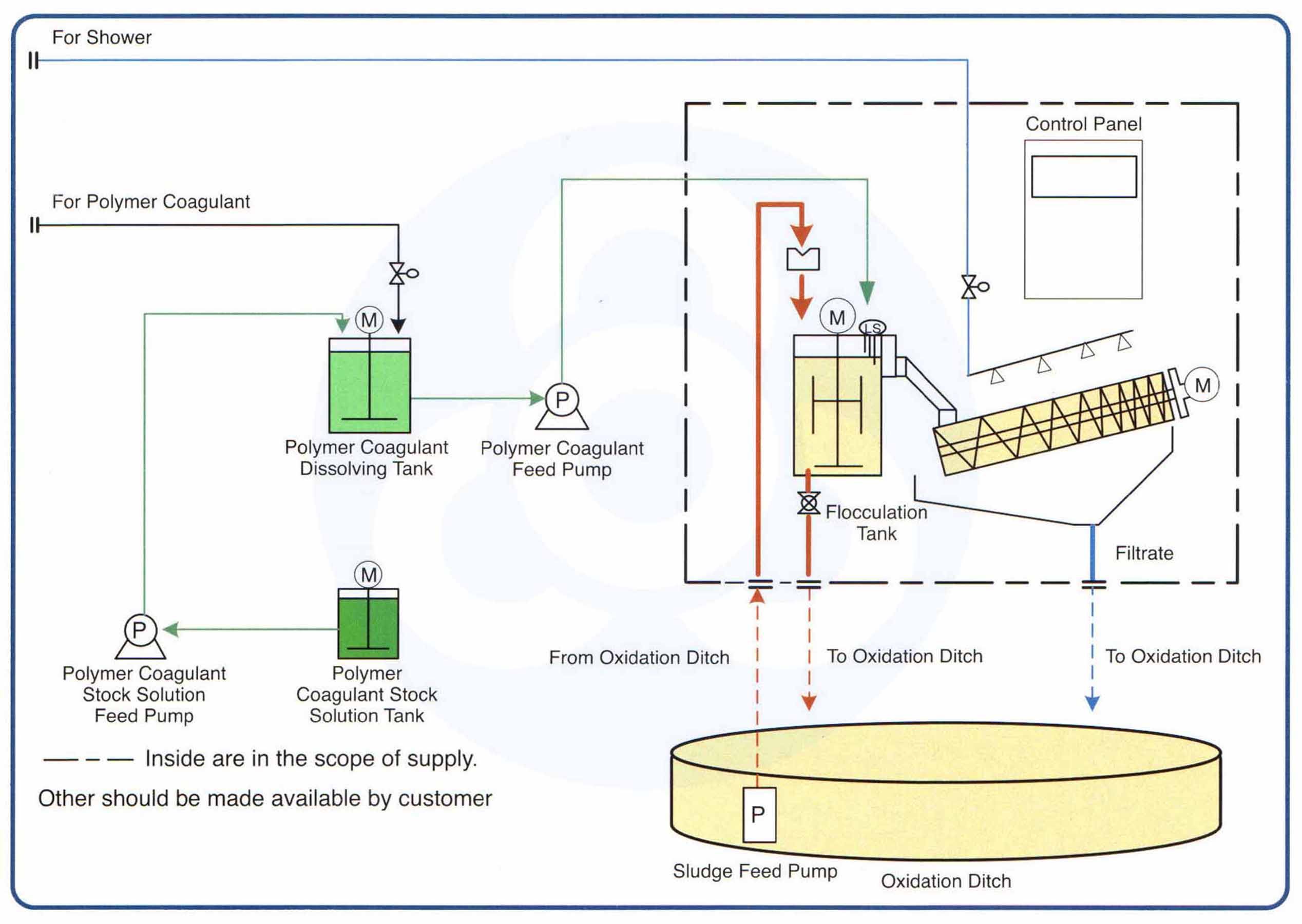

Sludge Dehydrator (Clog-free Multi-Disc Screw Press) |

|

�@ |

�@ Screw Press Sludge Dehydrator Multi-Disc / Clog-free / Automatic Japanese Technical Cooperation

�@ "Non-clogging screw press dehydrator" is also known as <Multi-Disc screw press dehydrator>, is a novel structure, a landmark progress of the multi-disk type, outer ring shape screw press sludge dehydrator. The sludge dewatering equipment is an Innovative design. Dehydrator structure is simple and durable, in recent years has been gradually applied to all types of sludge dewatering. �@

�@ Our engineering and technical team has more than 30 years of experience in the treatment of wastewater sludge dewatering. It is highly recommended that the industry adopt this "non-clogging screw press dehydrator" (also known as Multi-Disc screw press dehydrator). This type of dehydrator is very Suitable for biological sludge and grease sludge dewatering.

This type of dehydration machine will fully replace the poor function, cost,

high failure rate of old with filter sludge dewatering machine and

centrifugal sludge dewatering machine. Not only frequent failures, but also large power consumption, waste a lot of filter cloth cleaning water (cleaning water needs to be re-treated). It will cause the environment of sludge dewatering room bad, wet and noisy, operators dislike such work environment. Today, we and the most other engineers evaluate it as the industry's "money eating monster"! As for the high rotation speed centrifugal dewatering machine, it has more ability to eat money. High power consumption and maintenance costs, often make operators complain! After a few years of use, the machine is getting old. it produces high-frequency sound and vibration. It is to make the factory staff afraid to near by! The current "Non-clogging screw press dehydrator" is the best solution! Industry should be as soon as possible to replace the old filter-cloth sludge dewatering machine and centrifugal sludge dewatering machine. Try to reduce waste water treatment plant operation and handling costs, reduce operator labor costs.

We have a very full data to prove, the economic benefits of investment

improvement are very high.Only about two years can recover invest cost.

Factories do not hesitate! Cut off the old type of "money eating monster"

quickly! �@

�@

�@

�@ Sludge Dehydrator (Clog-free Multi-Disc Screw Press) Advantages

�@ Sludge Dehydrator (Clog-free Multi-Disc Screw Press) compared with other types of dehydration machine

�@

�@ Sludge Dehydrator (Clog-free Multi-Disc Screw Press) Specification

�@

�@ �� Food processing industry dairy processing plants, beverage plants, winery, meat processing plants, pasta plants, edible oil plants, slaughter plants ... and other biological sludge, chemical sludge and oily sludge dehydration. �� Chemical Industry chemical plants, cosmetic factories, textile factories, paint factories, adhesive factories, detergent factories, pharmaceutical factories ... and so on biological sludge, chemical sludge and oily sludge dehydration. �� Manufacturing Industry Semi-conductor factories, steam locomotive manufacturing plants, steam locomotive parts factories, circuit board factories, electronics factories, dyeing and finishing factories, leather factories ... and other biological sludge, chemical sludge and oil sludge dewatering. �� Domestic Sewage urban sewer sewage treatment plants, urban township sewage treatment plants, water recycling centers, rural settlement sewage treatment plants, septic tanks ... and other primary sludge and biological sludge dewatering. �� Agriculture, Animal Husbandry livestock farms, pig farms, cattle farms, duck farms, farms, slaughterhouses, palm oil farms ... organic wastewater sludge, biological sludge dewatering and oily sludge dewatering.

��

Aquarium, Aquaculture, Fish And Vegetable Symbiotic Industry �@

�@

�@ |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Product |

Sludge Dehydrator (Clog-free Multi-Disc Screw Press) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

�@

�@

|

|

|

|

E-mail�Gservice@ding-hui.com.tw ADD�G11F, No.42, Sec. 4, Cheng-gong Rd., Taipei, Taiwan, R.O.C. |

�@

�@

Copyright © 2014 Ding Hui International Co., Ltd. All rights reserved.