|

�@ |

�@

|

Floating Porous Bio-ball

|

-

Ultra-high surface

area of microbial carriers, wastewater treatment can improve the

efficiency of 2 to 5 times.

-

Large number of

domesticated microorganisms, oxygen transmission efficiency of the best,

excellent fluidity.

-

Can effectively

remove COD organic pollutants, and both excellent nitrification and

denitrification, suitable for wastewater ammonia nitrogen removal.

-

The biological

treatment tank has the advantages of simple structure, no need to set up

a platform, short construction period, and the best way to improve the

old activated sludge tank without emptying the tank body.

-

Reflux sludge is

easy to operate, sludge settling is good, no contact material clogging

problems.

Aeration power consumption less than 30%, low operating costs, energy

saving and waste reduction best.

-

Newly built

wastewater treatment plant or old wastewater treatment plant function

enhancements are applicable.

-

Super sludge

reduction effect, completely solve the problem of activated sludge

bulking and sludge aging.

-

Can effectively

improve water quality, reduce operating costs, is the best environmental

management system ISO14000 improvement programs.

|

|

Fiber Media Rapid Filter

|

-

Ultra-low filter

impedance, saving more than 50% of electricity.

-

Backwash water volume is very

small, compared with the traditional sand filter to save 80 to 90% of

the backwash water.

-

Ultra-high filtration speed,

saving more than 75% of the land than traditional sand filtration.

-

Better filtration

of water quality, SS removal rate higher than the sand filter 20 to 30%.

-

Fully automated

operation, filter backwash time as long as 10 minutes.

-

Filter is not

blocked, wear small, low failure rate, long service life.

-

The new "high-speed

fiber filter ", the payback period is only 0.5 to 2 years.

-

It can be used to

improve the quality of discharged water and reduce the cost of water

pollution prevention and control. Is the best environmental management

system ISO14000 pollution improvement program.

|

|

SLS Solid-Liquid Separator

|

-

Without the filter cloth, do

not need to use filter cloth cleaning water, effectively saving water.

-

Not blocked, automatic cleaning,

low speed, no noise or vibration, less power consumption, operation and

maintenance costs are very low.

-

Large capacity, can be used as a

sludge thickener or sludge dewatering machine, no need to clean the

filter cloth with water.

-

Simple structure, with a strip of

solid dirt cutting function, easy operation and maintenance.

-

Small size, space saving,

can be fully automated operation.

-

Suitable for waste water treatment

plants, food processing, pig farms, livestock farms, slaughterhouse

sludge dewatering and algae dehydration.

-

The best energy-saving and

water-saving sludge dewatering machine, can be the best

environmental management system ISO14000 pollution improvement program.

|

|

Turbo Blower |

-

Efficient air suspension bearings,

without adding lubricating oil, clean pressurized air supply.

-

High-speed permanent magnet

synchronous motor without vibration, low noise (less than 75dB), small

size, simple structure.

-

High efficiency, no slip, no rotor

friction loss.

-

Fast start-up reaction time, life

expectancy is much higher than the AC motor.

-

High efficiency inverter over 96%

high efficiency and stability.

-

Self-cooling system, no separate

cooling water circulation system.

-

Applied to wastewater treatment

plant aeration system, the payback period is within 2 years.

-

Saving more than 40% of

electricity, the best environmental management system ISO14000

improvement program.

|

|

Organic microbial nutrient

|

-

Strengthen microbial activity and environmental

adaptability, contribute to the biodegradable removal of

organic pollutants which is hard to degrade in wastewater.

-

Contains a variety of microbial growth and

trace elements, completely non-toxic, persistent long, no residue.

-

Enhance microbial activity and stability, delay

sludge aging, improve sludge dewatering characteristics.

Increase the sedimentation of sludge, reduce the ratio of reflux sludge,

save energy, and flexibly adjust the operation mode.

-

High concentration, dosage is very small, low

cost, can be completely or 60 ~ 90% alternative urea, completely replace

the use of phosphate.

-

Reduce the cost of traditional urea and

phosphate by 20 ~ 40%, reduce the operating cost of industrial

wastewater treatment.

-

Effectively improve the COD removal of

wastewater removal rate, improve sludge sedimentation, prevent sludge

bulking (sludge bulking).

-

Improve wastewater treatment efficiency of

biological treatment system, the best environmental management system

ISO14000 improvement program.

|

|

Supra Magnet Fluid Activator

|

-

Improve the boiler scaling phenomenon, improve

thermal efficiency, energy saving and waste reduction best, and extend

the boiler life.

-

Prevent boiler equipment to generate scale,

reduce energy consumption by 5 ~ 25%.

-

Reduce the host of ice water, water-cooled air

compressor and a variety of heat exchange system drainage loss of 80 to

95%.

-

Suppression of mycelium growth in cooling

towers and cooling circulating water.

-

Reduce the host of ice water, water-cooled air

compressor and cooling tower descaling, corrosion chemical agents to

reduce costs and pollution.

-

Anti-corrosion oxidation, to extend the life of

a variety of heat exchange system equipment.

-

With excellent water saving carbon reduction

effect, the investment recovery period of only 0. 3 to 2 years.

-

With excellent water-saving carbon reduction

effect, the best environmental management system ISO14000 improvement

program.

|

|

Sludge Dehydrator

|

-

Biological aeration tank Low concentration of 2,000mg / L to MBR

aeration tank High concentration 50,000mg / L of sludge can be directly

dehydrated, completely solve the sludge anaerobic odor problems.

-

No initial set minimum cost, the smallest space.

-

With self-cleaning ability, does not produce sludge clogging phenomenon,

cleaning machine water consumption is about 1/200 of the belt press

sludge dewatering machine.

-

System equipment can be a key start to run, to be fully automated,

without people on-site operation, saving manpower.

-

Equipment failure rate is low, no maintenance management issues.

-

Low speed, no vibration or noise, less power consumption, low operation

and maintenance costs.

-

Small footprint, easy to install, compared with the belt press sludge dewatering

machine and centrifugal sludge dewatering machine, the replacement of the

new sludge dehydrator is the best new choice.

-

Improve sludge dewatering efficiency, is the best environmental

management system ISO14000 improvement program.

|

|

UV Sterilizer

|

-

Physical sterilization, drug-free

no contamination, automatic, fast, harmless disinfection and sterilization

equipment.

-

Ultraviolet (UV) illumination

super, rapid and effective disinfection and sterilization capabilities,

no potential harm to the human body.

-

The latest amalgam UV lamp, high

efficiency, saving space.

-

Can be equipped with automatic

quartz glass tube surface cleaning device, eliminating the glass tube

and lamp cleaning disassembly trouble.

-

Applications As a water

sterilization and algae removal equipment, the effect is excellent, can

also be used as wastewater COD advanced oxidation treatment equipment.

-

Suitable for swimming pool

sterilization, water recycling sterilization and waste water discharge

and sterilization of the best domestic UV disinfection equipment.

-

Swimming pool, landscape pool, hot

spring pool sterilization best tool.

-

Reduce the addition of

bactericidal agents, no carcinogens, is the best environmental

management system ISO14000 improvement program.

|

|

Paddle Dryer |

-

Low speed rotation, low blade and

shaft wear.

-

Less dust entrainment, low noise,

exhaust gas treatment easy.

-

Rotary shaft can be engaged with

each other, automatically clean the sludge on the heating surface, to

prevent material sticky wall.

-

Use saturated steam as a heat

source and do not require additional fuel for combustion.

-

Evaporation can be recovered, to

avoid toxic and harmful gases.

-

With a slight negative pressure to

remove moisture, dust recycling convenience, perfect exhaust treatment

device.

-

Sludge dryer investment recovery

period of only 0.5 to 1 year or so.

-

Thermal efficiency of more than

90% of the sludge reduction equipment, is the environmental management

system ISO14000 excellent improvement program.

|

|

Rotary Dryer |

-

The VOC gas generated during

drying can be used as the drying air for the material to be dried. The

exhaust gas is odorless.

-

Bag filter dust removal dust

treatment, no dust pollution.

-

Drying and deodorization are

simultaneous, with less fuel consumption than other dryer types.

-

Rotary cylinder containing

crushing shaft inside, improve drying efficiency, make the device more

compact.

-

Equipment wear rate is extremely

low, easy operation and maintenance, can be automated operation.

Drying speed can be recovered methane methane as fuel.

-

Sludge dryer investment recovery

period of only 0.5 to 1 year or so.

-

Low energy consumption of sludge

reduction equipment, is an excellent environmental management

system ISO14000 program.

|

|

Rapid Composting Machine |

-

Save energy, low

operating costs, make full use of space, small footprint.

-

Applied to

organic sludge, pig manure, livestock and poultry residues, kitchen

waste and other organic materials recycling and recycling as composting.

-

Automatic

control, remote monitoring.

-

Process closed,

no secondary pollution.

-

The use of

microbial deodorization, odorless process of production.

-

aterials contact

parts of stainless steel 304, corrosion-resistant, long service life.

-

Equipped with

auxiliary air supply and heating device to ensure the normal operation

of equipment in low temperature environment.

-

Composting and

reusing organic waste makes it consistent with the global recycling

economy. The investment recovery period is only about 1 to 2 years.

-

Excellent

organic solid waste rapid composting recovery unit, is the environmental

management system ISO14000 excellent improvement program.

|

|

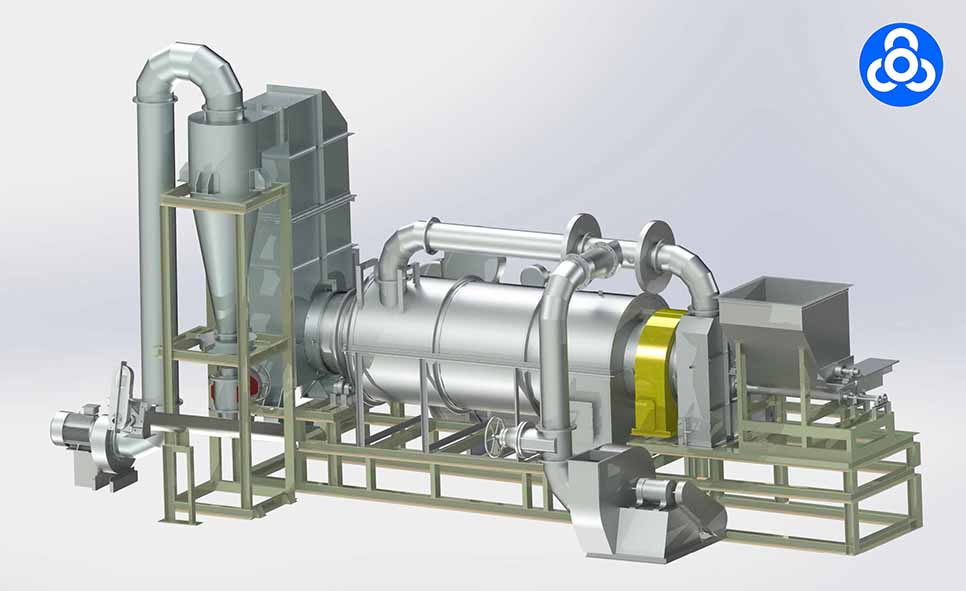

Carbonizer |

-

Operating costs are extremely low,

volatile gas produced by carbonization can be used as carbonized fuel,

effective recovery of heat re-use.

-

Organic sludge carbonization,

volume and total reduction of more than 90%.

-

Carbonized products harmless, can

be used as a humidity control material, carbon steel reduction

materials, soil improvement materials, deodorization of carbon

materials, water purification with carbon, fuel carbon ..., has a wide

range of applications.

-

Operation is simple, short

processing time, small footprint.

-

Evaporation can be recovered, to

avoid toxic and harmful gases.

-

Recycling of organic materials is

in line with the circular economy approach to global development and

enhances the carbon recycling rate.

-

Recycled carbon products with

market value, high economic efficiency, equipment investment recovery

period of 3 years.

-

Excellent organic solid waste

carbonation recovery unit, is the institution of environmental

management system ISO14000 best improvement program.

|

�@ �@ |