|

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

�@

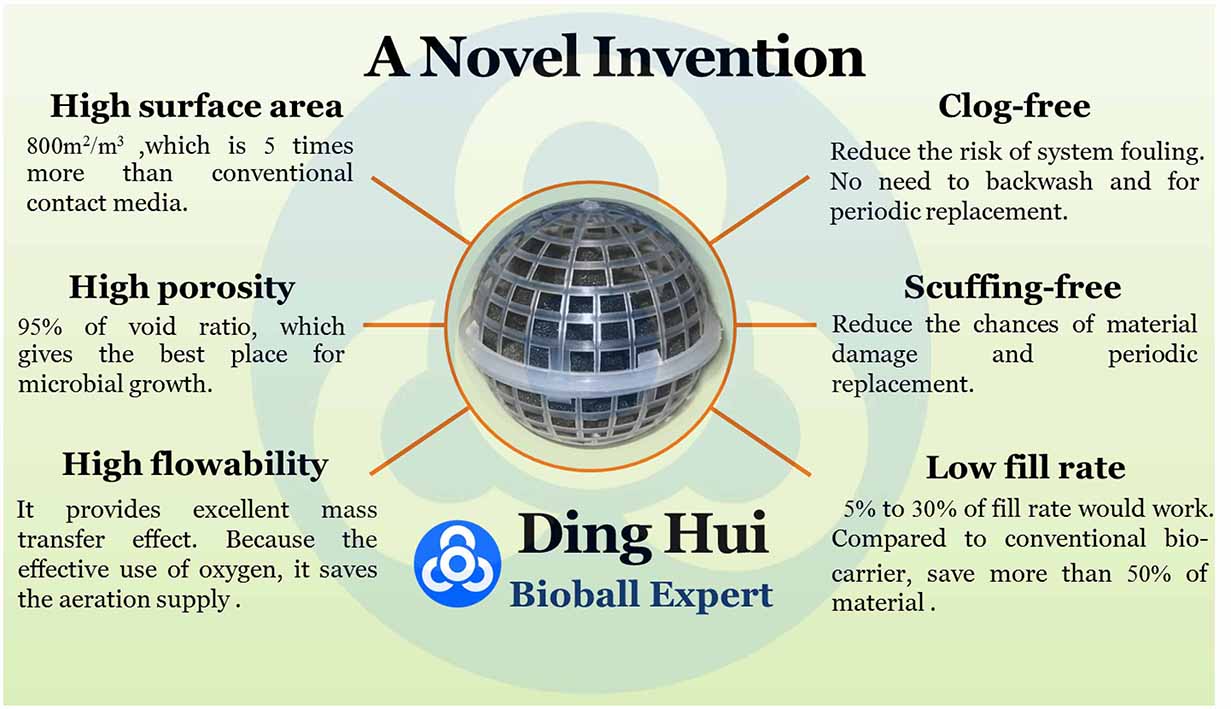

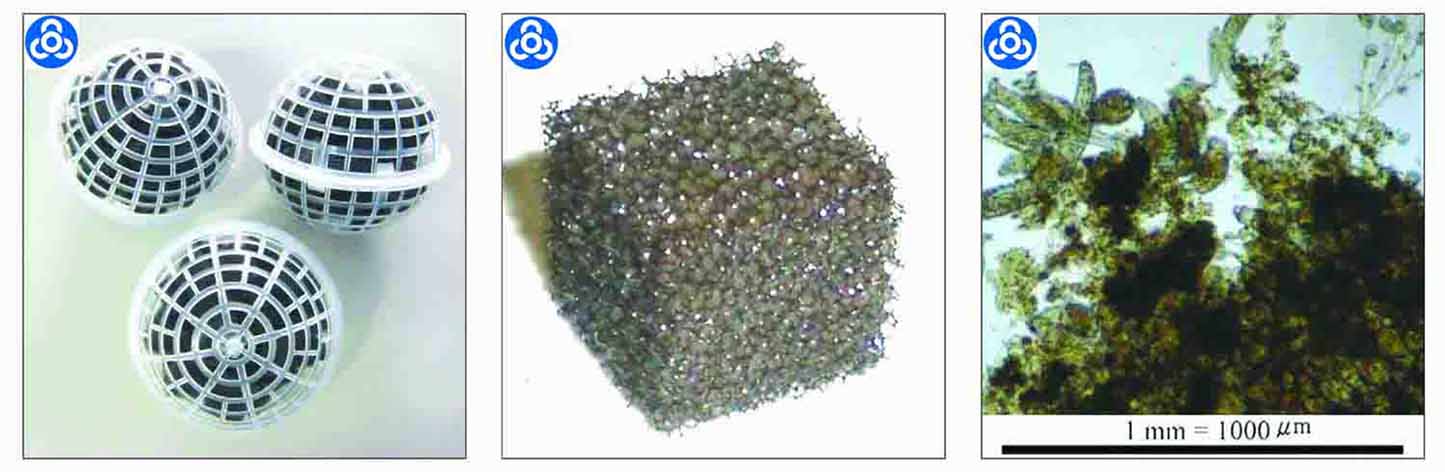

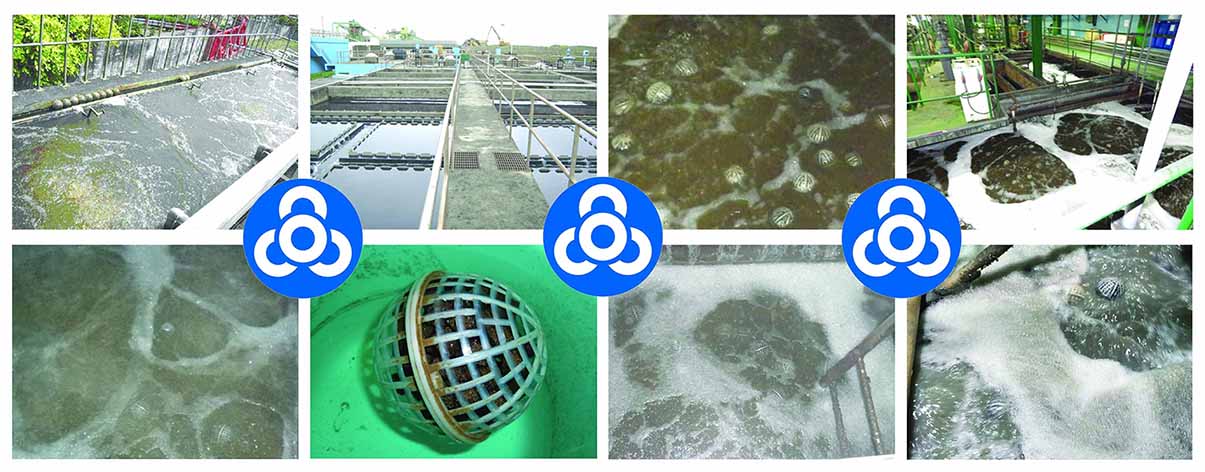

Floating porous biological ball is currently

the world's best bio-filter (microbial carrier), its effectiveness than

porous ceramic, rope contact material, mesh contact material, BIONET foam

support, plastic suspension ball, honeycomb contact material, the wave plate

Type contact material, three-dimensional mesh packing (contact material),

MBBR packing �EK1 packing, K2 packing, K3 packing and various mesh packing,

filiform packing, plastic packing, biochemical ball ...

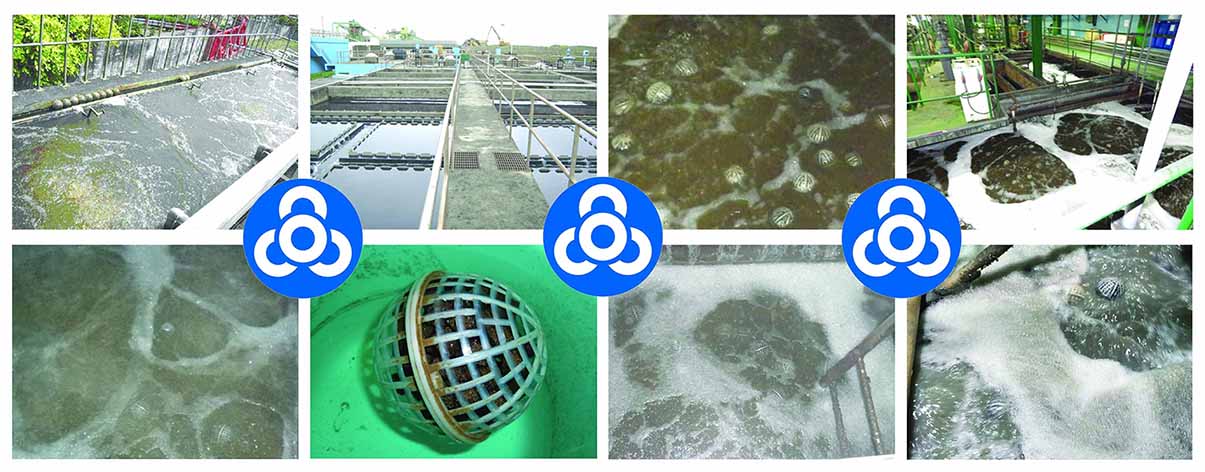

Floating porous biological ball is a microbial support, contact material,

bio ball, bio-ball, bio_ball, bioball, suitable for anaerobic fluidized bed,

anaerobic treatment system, anaerobic treatment system, anaerobic digestion

tank, anorexia The performance of filter bed, anaerobic filter bed,

anaerobic treatment, UASB, A2O method, AO method, ABF, aeration tank,

aeration tank, biological reaction tank, biochemical reaction tank, Sludge

Bulking bulking problems, sludge sedimentation rate increase, improve SV30

and sludge volume index, to enhance the biological aeration tank volume

load, shorten the biological reaction tank hydraulic retention time, improve

the biological sludge dewatering efficiency, with excellent nitrification

and denitrification (Denitrification) and phosphorus removal effect, which

can effectively domesticate Anammox bacteria and various aerobic and

anaerobic sludge. The microorganism phase is good and the number of ethnic

groups is abundant, which can aid in the production of granular anaerobic

sludge, enhance the perspective of releasing water and live Sewage ammonia

removal rate is the highest, can also reduce the effluent nitrate

concentration, long service life, low wear and tear, good flow, and improve

aeration oxygen efficiency, difficult to decompose organic pollutants in

wastewater Of the removal capacity, impact load, can also be used for sludge

digestion and reduction, and can improve the MBR system processing capacity,

increase the amount of water to slow down the filter clogging, low

concentration of organic wastewater can be used in the treatment of fixed

bed organisms Filtration also has very good results, fluidized bed

biological treatment has the role of flow mixing, mass transfer and oxygen

transmission more superior, welcome to use CDH (DHI) to develop a successful

floating porous biological ball.

�@

�@

�@

�@

�@

�@ |

�@

|

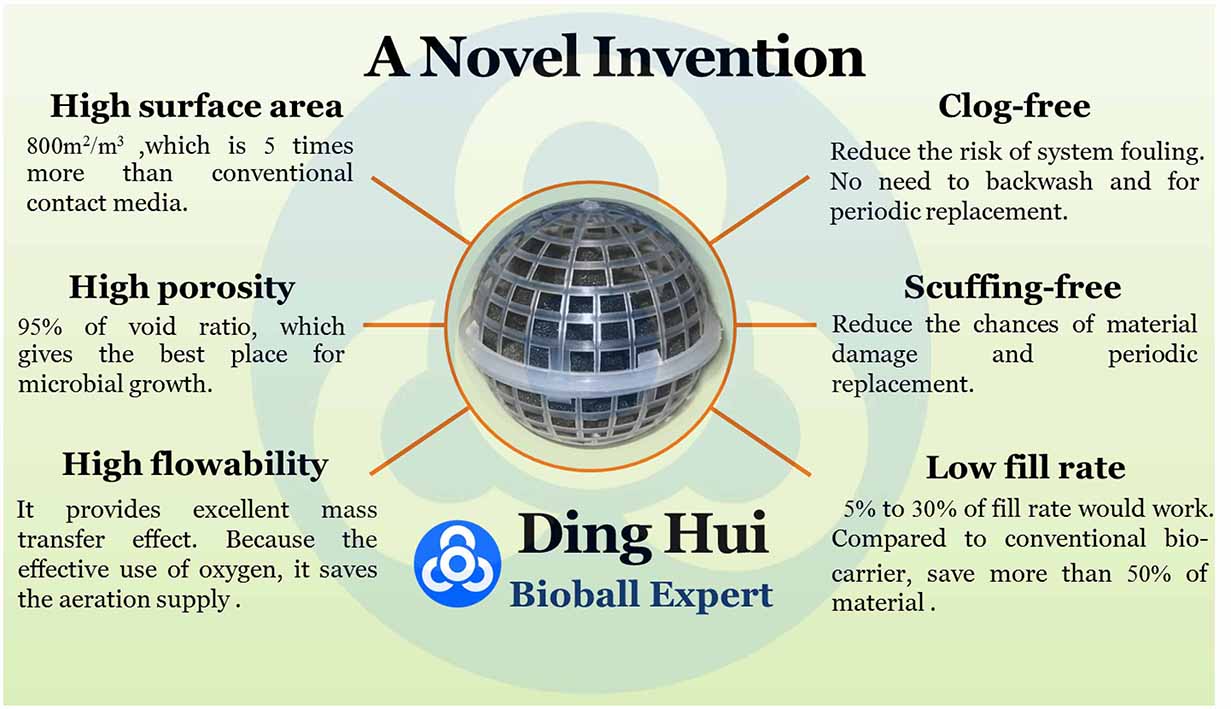

The Most Optimized

Bio-carriers |

The world's best denitrification and COD removal contact material

Invented and Manufactured by DING HUI

�@

�@

�@

|

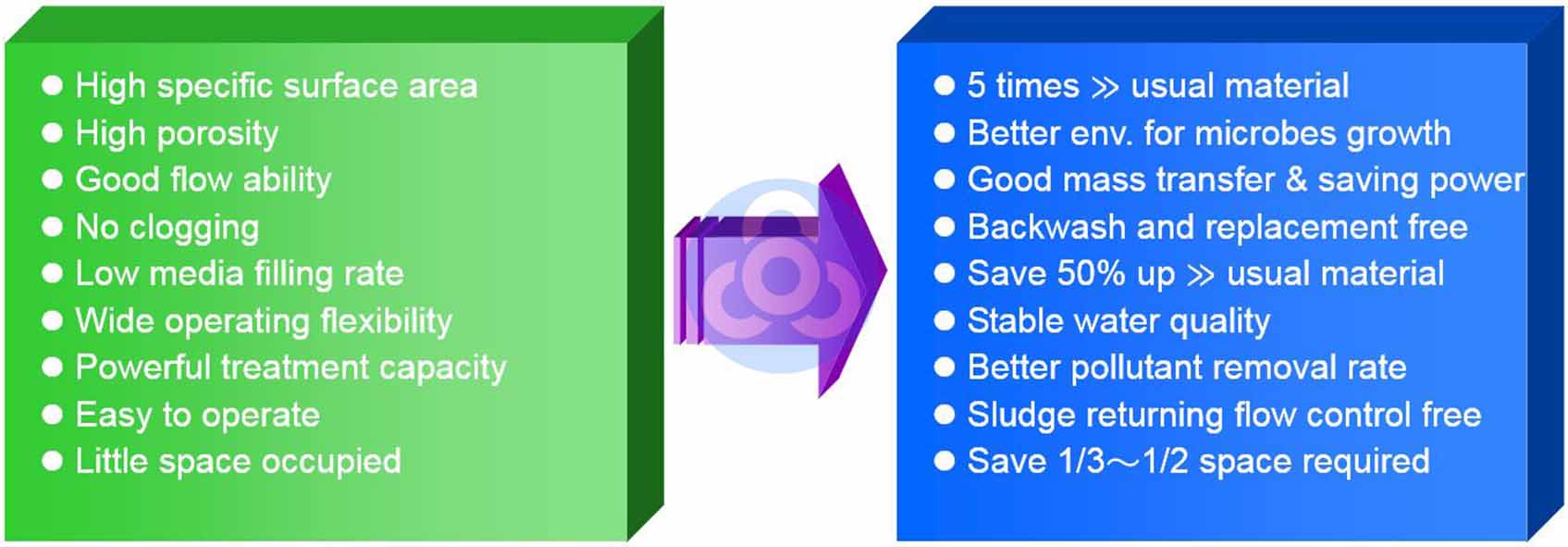

Innovative Technique for Organic

Wastewater |

�@

My company's technical staff with more than 30 years of factory

pollution control and waste reduction recycling experience. After

long-term accumulation of experience and research and testing, finally

breaking the bottleneck of existing wastewater treatment technology. We

created a new method of Floating Porous Bio-ball wastewater treatment (FPB

method).

The FPB method is a superior new technology for wastewater biological

treatment, which can save energy and increase the removal rate of

pollutants in wastewater. It will become the mainstream technology of

wastewater biological treatment in the future.

The successful development of FPB method in the world will greatly

enhance the functions of wastewater treatment systems and make a

significant contribution to improving water pollution.

Our company can assist public and private organizations and industry to

diagnose the function of wastewater treatment system and provide the

most economical and optimized use of FPB method. Whether it is new or

old wastewater biological treatment system, the treatment efficiency can

be improved by 10 % ~ 50%, or even higher, please make a lot of use. �@

�@

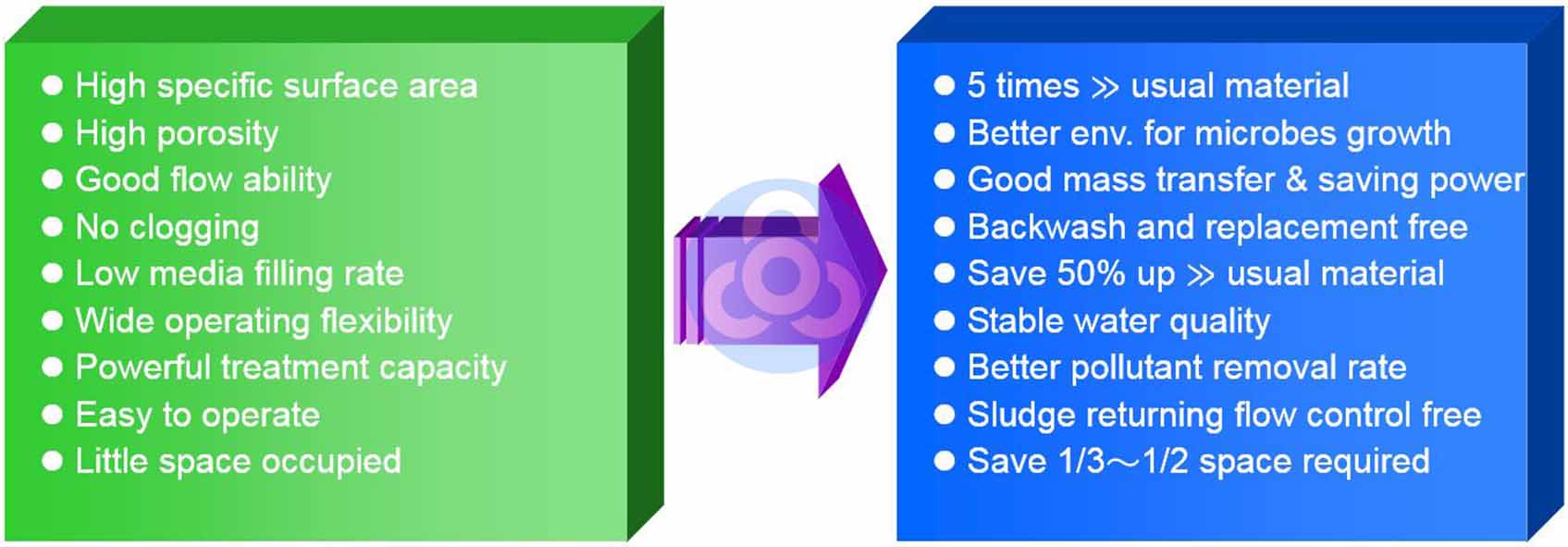

Floating porous

bio-ball wastewater treatment technology (FBP method) combines the

advantages of activated sludge method and contact aeration method,

drastically simplifying the biological wastewater treatment system

operation, improve wastewater organic pollutants and ammonia nitrogen

(TN) removal efficiency.

|

��

Easy set-up

��

Easy operation

��

Durability

|

��

Failure Recovery

��

Flexibility

��

Reliability

|

�@

�@

|

Comparison

of Biological Treatment Process |

�@

|

|

Flotating Porous

Bio-ball |

MBR |

Contact aeration |

Activated Sludge

|

|

Volume loads (g COD/m3�Ed) |

1,000��3,000 |

1,000��2,000 |

300��1,000 |

400��800 |

|

Aeration flow requiring |

Few |

Large |

Large |

Large |

|

Oxygen transfer |

Excellent |

Low |

Fine |

Low |

|

Sludge settleability |

Excellent |

Low |

Fine |

Not stable |

|

Sludge bulking |

Never |

Frequent |

Seldom |

Frequent |

|

Sludge reduction |

Excellent |

Fine |

Fine |

Low |

|

Sludge dehydration |

Easy |

Difficult |

Fine |

Not stable |

|

Operation flexibility |

Easy |

Very difficult |

Fine |

Difficult |

|

Power consumption |

Low |

High |

High |

High |

|

Organics removal rate |

High |

High |

Low |

Fine |

|

Nitrous/phosphorous removal |

High |

Fine |

Fine |

Low |

|

System fault rate |

Stable |

Clog |

Clog |

Not stable |

|

Material replacement period |

≥ 8

yr |

1��2

yr |

3��5

yr |

----- |

|

Total cost $ |

Save money |

Waste money |

Fine |

----- |

�@

|

|

Solar Wafer production field |

Print Circuit Board field |

Dyeing and Finishing field |

�@

Food processing field

�@ |

|

Flow |

3,000 CMD |

60 CMD |

1,000 CMD |

1,200CMD |

|

Fill rate |

15% |

15% |

20% |

15% |

|

COD inlet |

750 mg/L |

4,000 mg/L |

1,200 mg/L |

1,100 mg/L |

|

COD effluent |

��100 mg/L |

200��400

mg/L |

��200 mg/L |

��100 mg/L |

�@

|